Business news | July 28, 2023

By Nick Flaherty

MATERIALS & PROCESSES POWER MANAGEMENT

Infineon Technologies is using a recyclable PCB technology for its power demonstration boards in an move to cut electronic waste.

Infineon is using Soluboard biodegradable PCBs from Jiva Materials in the UK for the power demo boards.

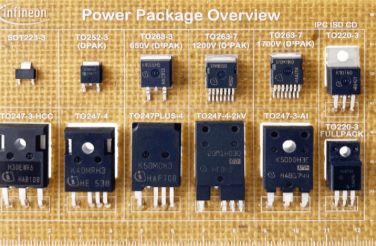

More than 500 units are already in use to showcase the company’s power discretes portfolio, including one board that features components specifically for refrigerator applications. Based on the results of ongoing stress tests, the company plans to provide guidance on the reuse and recycling of power semiconductors removed from Soluboards, which could significantly extend the lifetime of the electronic components.

The plant-based PCB material is made from natural fibres, which have a much lower carbon footprint than the traditional glass-based fibres in FR4 PCBs. The organic structure is enclosed in a non-toxic polymer that dissolves when immersed in hot water, leaving only compostable organic material. This not only eliminates PCB waste, but also allows the electronic components soldered to the board to be recovered and recycled.

● Mitsubishi invests in green startup PCB maker

● Building the world’s first biodegradable plastic chips

● Eco-friendly NFC tag with paper-based antenna substrate

“For the first time, a recyclable, biodegradable PCB material is being used in the design of electronics for consumer and industrial applications – a milestone towards a greener future,” said Andreas Kopp, Head of Product Management Discretes at Infineon’s Green Industrial Power Division. “We are also actively researching the reusability of discrete power devices at the end of their service life, which would be an additional significant step towards promoting a circular economy in the electronics industry.”

“Adopting a water-based recycling process could lead to higher yields in the recovery of valuable metals,” said Jonathan Swanston, CEO and co-founder of Jiva Materials. “In addition, replacing FR-4 PCB materials with Soluboard would result in a 60 percent reduction in carbon emissions – more specifically, 10.5 kg of carbon and 620 g of plastic can be saved per square meter of PCB.”

Infineon is currently using the biodegradable material for three demo PCBs and is exploring the possibility of using the material for all boards to make the electronics industry more sustainable.

The research will also provide Infineon with a fundamental understanding of the design and reliability challenges customers face with biodegradeable PCBs in designs. In particular, customers will benefit from the new knowledge as it will contribute to the development of sustainable designs.

Post time: Sep-13-2023